A new standard for strong

and stackable packaging

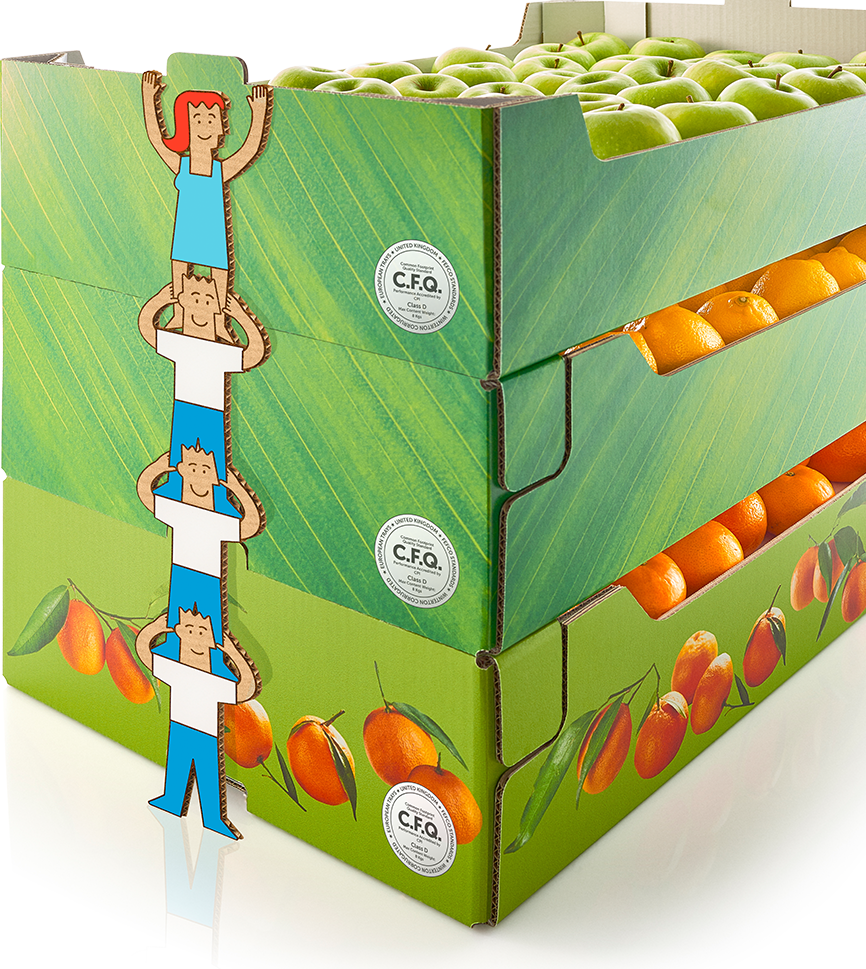

The new European-wide Common Footprint Quality (CFQ), promises stackable, top quality, fit for purpose corrugated packaging. CFQ accredited trays deliver the protection needed by delicate fruit and vegetables, giving growers and retailers assurance that their fresh produce will arrive in store in optimum condition every time.

CFQ builds on the FEFCO Common Footprint (CF), which harmonises tabs and noses of corrugated trays throughout Europe. CF guarantees the stackability that allows growers and retailers to handle transport of fruit and vegetables efficiently; the Q promises quality and strength.

CFQ accredited trays consider both the type of fresh produce being packed and the distance it must travel. This makes them the best choice for retailers looking for strong packaging that is able to cushion, carry and protect fruit and vegetables throughout their journeys.

CFQ accredited trays for safe, efficient logistics

![]()

Consistently high performance :

The strength and durability of any tray carrying the CFQ stamp has been rigorously tested to ensure it is fit for purpose while optimising handling and transportation.

![]()

Simplicity for your supply chain :

The CFQ stamp offers assurance that trays can be stacked safely and quickly so distribution centres can handle trays from different origins, stacking them on top of each other with ease.

![]()

Optimised transportation :

Light and modular, with standardised bases and variable heights, CFQ trays offer the best weight to volume ratio for shipments, maximising truck loads and minimising transportation costs.

![]()

Cross-border compatibility :

The modular CFQ trays are strong and fit for purpose. In Europe, all trays with the CFQ logo are compatible, facilitating handling and logistics operations.

![]()

Assured quality:

Use of the CFQ stamp is only granted to corrugated manufacturers once their trays have been audited to ensure they meet CFQ’s strict technical specifications.

Built-in resistance for

storage and transport

Strict technical specifications mean retailers can be confident that the CFQ trays will protect their fresh produce and ensure it arrives in store in perfect condition. A variety of tests are carried out to confirm that trays adhere to the standards:

Resistance to vertical compression:

The Box Compression Test verifies that CFQ trays stacked on a pallet, especially those at the bottom, are able to support the weight of those above without being crushed.

Resistance to bending:

The Static Bottom Deflection Test verifies that CFQ trays are resistant to sagging under the weight of produce, ensuring the fruit and vegetables in the trays beneath are kept safe.

Resistance to moisture and fluids:

Water absorption tests (Cobb method) verify that, when kept under the correct storage conditions, the corrugated in CFQ trays can absorb a defined amount of moisture or fluid while maintaining the characteristics of the tray.

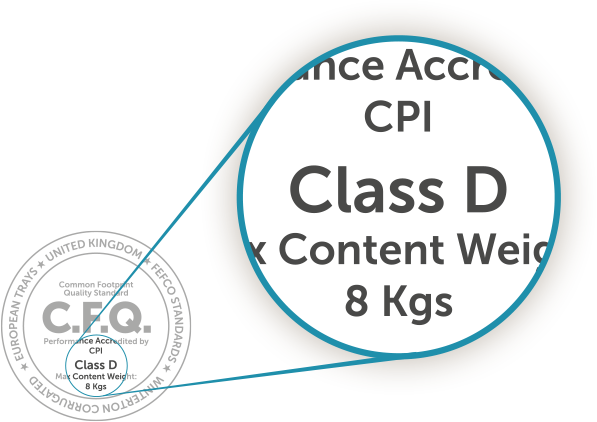

Going the distance

CFQ certifies the maximum load that tray can

carry and uses a coding system to indicate

the distance the fresh produce can

safely travel in that tray:

Efficiency from grower to retailer

The CFQ tray’s variable height, along with its construction and choice of papers, can be adapted to ensure it’s an ideal fit for the produce it’s carrying yet as light as possible. Standardised interlocking tabs and matching receptacles ensure CFQ trays of different heights can be stacked together safely and efficiently.

The CFQ tray’s standardised base size corresponds to sub-multiples of pallets allowing efficient use of the pallet footprint. CFQ trays fit perfectly onto a standard pallet or half pallet, avoiding gaps and pallet overlap so space can be used optimally, even with mixed loads.

This perfect combination of space optimisation and ideal packaging weight optimises transportation, allowing companies to reduce fuel consumption and CO2 emissions – saving energy, cost and the environment.

Harmonised modular trays

The CFQ standard gives assurance that every tray is an ideal fit for its produce while optimising transportation. Equally important, CFQ trays from different producers in different countries can be stacked together.

A network of corrugated manufacturers can produce standardised CFQ trays quickly and deliver just in time to meet seasonal demand peaks from their locations near growing areas, cutting down on stock levels throughout the supply chain.

The stamp of quality

All tray testing is performed externally under standard conditions prescribed by FEFCO and continuously monitored by the National Associations of Corrugated Board Manufacturers. Their independent auditors use their own control laboratories to regularly audit tray producers.

For corrugated manufacturers, non-compliance with the CFQ standards means increasingly dissuasive fines. They may even be banned outright from using the label.

Printable packaging sells more

Like all corrugated packaging, CFQ trays are perfectly designed for displaying fruit and vegetables. Their printability makes them an ideal communication and promotional tool for growers and retailers. By conveying information on quality, ripeness, brand, country, locality of origin and more, in attractive full colour, they help to increase sales.

Protecting produce

As corrugated packaging, CFQ trays are designed to take particular care of all kinds of delicate produce. They provide perfect cushioning, control ventilation, mitigate temperature changes and keep dust and light out.

Only ever used once, the trays are always new and perfectly clean. Rigorous scientific research [LINK re Bologna study] has proven that corrugated trays expand shelf life of fruit and vegetables with up to 3 days.

Protecting the environment

Corrugated packaging cares for the environment too: it’s renewable, biodegradable and 100% recyclable. Retailers bale their used trays, then send them a local recycling facility or paper mill. More than that, corrugated itself is made of 88% recycled materials. CFQ tray’s stackability optimises truck space and transportation, saving energy and costs while reducing CO2 emissions and waste.

National organisations, such as UNIQ in Spain and Bestack in Italy, in collaboration with FEFCO, have each implemented a local

control system to ensure their members meet CFQ’s strict technical specifications.